Green hydrogen

Green hydrogen: an alternative that reduces emissions and cares for our planet

The decarbonisation of the planet is among the objectives that countries around the world have set for 2050. The production of green hydrogen, a technology based on the transformation of this element through electrolysis, is one of the keys. The IEA estimates that it would make it possible to save the 830 million tonnes of CO2 per year that originate when this gas is produced using fossil fuels.

Green hydrogen, an alternative when electrification is not possible.

Learn how green hydrogen is extracted.

Green hydrogen is efficient and 100 % sustainable, with some experts predicting that it will be the fuel of the future.

Iberdrola, a global energy leader, anticipates once again by promoting green hydrogen.

Our way of life needs an increasing amount of watts to function. The war in Ukraine has caused a global energy crisis due to the lack of fossil fuels. This has led to an unprecedented rise in the price of natural gas and coal, causing Europe to import much more liquefied natural gas than usual, with the attendant problem of worsening climate change. However, decarbonising the planet suggests a different world in 2050: one that is more accessible, efficient and sustainable, and driven by clean energies such as green hydrogen.

What is green hydrogen an how is it obtained?

This technology is based on the generation of hydrogen — a universal, light and highly reactive fuel — through a chemical process known as electrolysis. This method uses an electrical current to separate the hydrogen from the oxygen in water. If this electricity is obtained from renewable sources we will, therefore, produce energy without emitting carbon dioxide into the atmosphere.

As the IEA points out, this method of obtaining green hydrogen would save the 830 million tonnes of CO2 that are emitted annually when this gas is produced using fossil fuels. Likewise, replacing all grey hydrogen in the world would require 3,000 TWh/year from new renewables — equivalent to current demand of Europe. However, there are some questions about the viability of green hydrogen because of its high production cost; reasonable doubts that will disappear as the decarbonisation of the earth progresses and, consequently, the generation of renewable energy becomes cheaper.

How is green hydrogen obtain?

Producing green hydrogen by electrolysis from renewable sources involves breaking down water molecules (H2O) into oxygen (O2) and hydrogen (H2).

Source: U.S. Department of Energy and Wood Mackenzie.

SEE INFOGRAPHIC: How is green hydrogen obtained? [PDF] External link, opens in new window.

SEE INFOGRAPHIC: How is green hydrogen obtained? [PDF] External link, opens in new window.

Hydrogen as clean energy

Hydrogen is the most abundant chemical element in nature. As noted by the IEA, the global demand for hydrogen for use as a fuel has tripled since 1975 and reached 70 million tonnes a year in 2018. In addition, green hydrogen is a clean energy source that only emits water vapour and leaves no residue in the air, unlike coal and oil.

Hydrogen has a long-standing relationship with industry. This gas has been used to fuel cars, airships and spaceships since the beginning of the 19th century. The decarbonisation of the world economy, a process that cannot be postponed, will give hydrogen more prominence. In addition, if its production costs fall by 50 % by 2030, as predicted by the World Hydrogen Council, we will undoubtedly be looking at one of the fuels of the future. International Day of Clean Energy highlights the importance of clean energy technologies for a more sustainable future.

![]() Access our webinar on green hydrogen

Access our webinar on green hydrogen

Advantages and disadvantages of green hydrogen

This energy source has pros and cons that we must be aware of. Let's go over some of its most important good points:

-

100 % sustainable: green hydrogen does not emit polluting gases either during combustion or during production.

-

Storable: hydrogen is easy to store, which allows it to be used subsequently for other purposes and at times other than immediately after its production.

-

Versatile: green hydrogen can be transformed into electricity or synthetic gas and used for commercial, industrial or mobility purposes.

However, green hydrogen also has negative aspects that should be borne in mind:

-

High cost: energy from renewable sources, which are key to generating green hydrogen through electrolysis, is more expensive to generate, which in turn makes hydrogen more expensive to obtain.

-

High energy consumption: the production of hydrogen in general and green hydrogen in particular requires more energy than other fuels.

-

Safety issues: hydrogen is a highly volatile and flammable element and extensive safety measures are therefore required to prevent leakage and explosions.

Impact of green hydrogen

Hydrogen as a fuel is a reality in countries like the United States, Russia, China, France and Germany. Others like Japan are going even further and aspire to become a hydrogen economy. Below we explain what the impact will be in the future:

Green and blue hydrogen

Discover the importance of hydrogen colours.

Green methanol and the maritime transport

This chemical compound is a promising alternative to fossil fuels.

What are hydrogen stations?

Hydrogen dispensers function as a refuelling station.

Green steel

The decarbonisation of steel allows for a reduction in emissions from this industry.

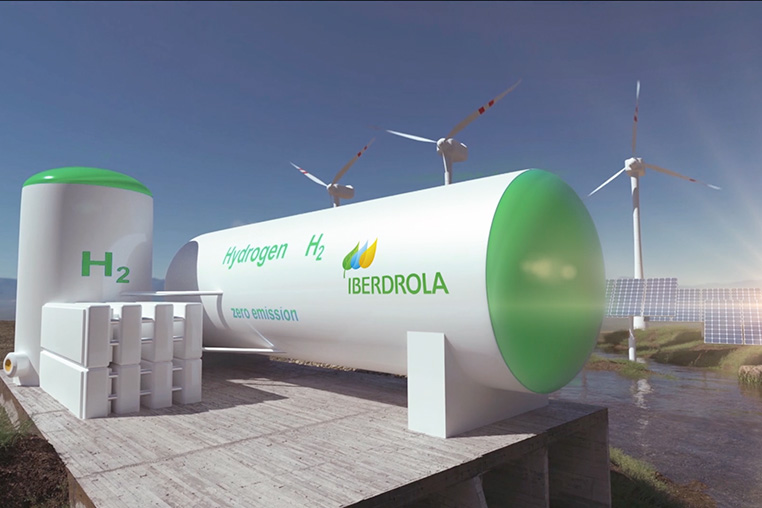

Iberdrola leads the development of green hydrogen

In its commitment to driving the energy transition, Iberdrola is leading the development of green hydrogen with three projects currently in operation in Spain and a fourth one scheduled to come online in 2026. The group is actively working on several projects – including e-methanol and green ammonia– in locations such as Europe, Australia or Brazil to respond to the needs of decarbonisation. As it did with renewables 20 years ago, the company has become a 'first mover' in this new technological challenge that involves the production and supply of green hydrogen.

Iberdrola is already developing projects that will enable the decarbonisation of industry (refineries, fertilisers, chemicals…)and heavy transport, as well as developing its value chain.

After establishing a solid foundation with real green hydrogen projects, Iberdrola is now taking the next step to develop projects at scale. In addition, Iberdrola has submitted numerous projects to various subsidy schemes at both European and global levels, achieving success in many of these programmes to secure funding support for our initiatives.