What is offshore wind energy

Do you know how offshore wind farms work?

Iberdrola projects Offshore wind

Offshore wind energy is the clean and renewable energy obtained by taking advantage of the force of the wind that is produced on the high seas, where it reaches a higher and more constant speed than on land due to the absence of barriers. In order to make the most of this resource, mega-structures are installed that are seated on the seabed and equipped with the latest technical innovations. Discover what these real sea giants are like and how they work.

How does offshore wind energy work? Video voice transcription (Spanish version) External link, opens in new window.

Offshore wind energy: the power of movement, the force that generates energy.

What are the advantages of offshore wind energy?

Where can offshore wind farms be installed?

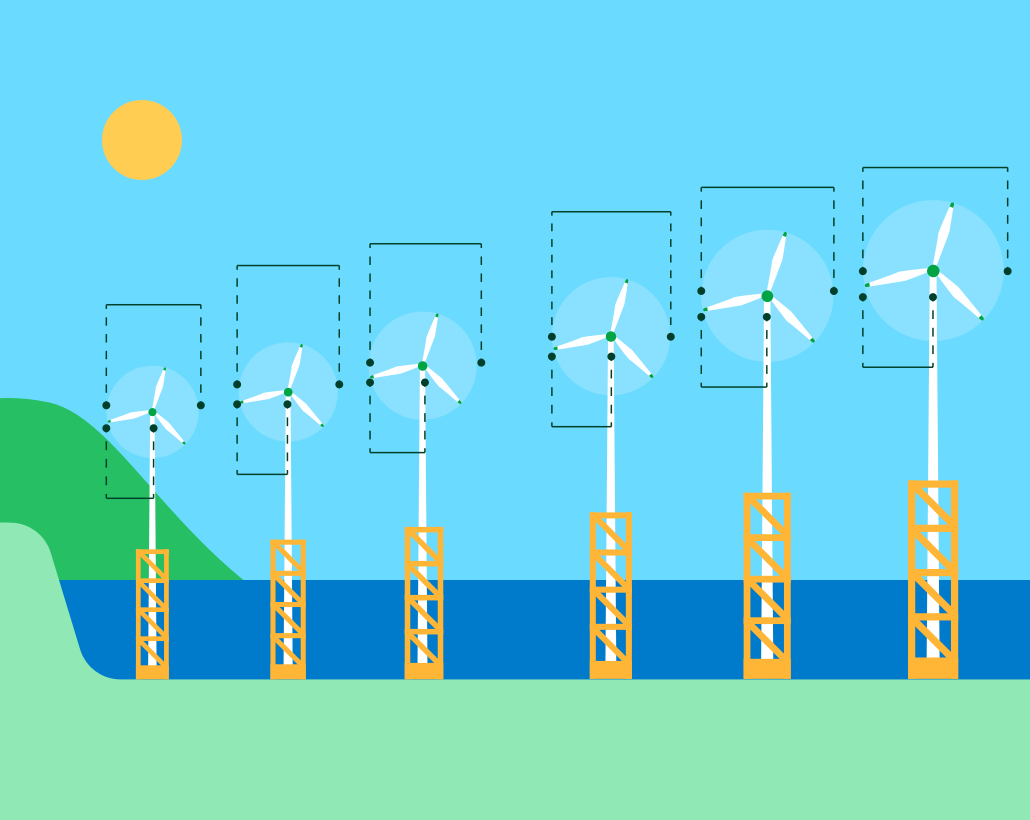

Offshore wind farms are installed in strategic locations where the wind passes at higher speeds and sea conditions make it technically feasible. Traditionally these installations have been built in shallow waters and close to the coast, where the structures could be anchored to the seabed.

However, technological advances have meant more and more installations can be located in deeper waters, even kilometres and kilometres from the coast, marine traffic routes, strategic naval installations and areas of ecological interest. According to recent data from the European wind energy association WindEurope, the average depth of offshore wind farms under construction in Europe now exceeds 36 metres, while the average distance from the coast is around 60 kilometres, a figure that has been increasing in recent years.

This trend is due to the search for a better use of wind resources in the open sea, where the wind is more constant and stronger, as well as to minimise the visual and environmental impact on coastal areas. In this sense, floating offshore wind opens the door to a key innovation for installing wind turbines on platforms that are anchored to the seabed, allowing them to be set up at sites further away from the coast.

How does an offshore wind farm work?

The offshore wind farms harness the power of wind over water to generate electricity in a clean and sustainable way. Located at sea, where winds are more constant and powerful, these farms are made up of large wind turbines anchored to the seabed by means of different types of supports or floating in deeper waters. The structure - whose height depends on the geography of the sea surface - is equipped with a beaconing system, with specific lights and colours that make it highly visible to maritime and air traffic for maximum safety.

The force of the wind turns the wind turbine blades, which are designed to capture as much of this kinetic energy as possible: they can move even in very light winds, starting at 11 kilometres an hour. Each turbine converts the kinetic energy of the wind into electricity via a generator, which is then transported through undersea cables to the coast to be fed into the electricity grid. This process represents a key solution for reducing CO₂ emissions and moving towards a greener future. The infographic below depicts the conversion from kinetic to electrical energy step by step.

Construction of an offshore wind plant

Everything about offshore wind farm construction.

Evolution of wind energy in Europe

The European wind market has grown strongly over the last 25 years. Find out more.

Floating offshore wind

A milestone to boost renewables through innovation.

How have offshore wind turbines evolved?

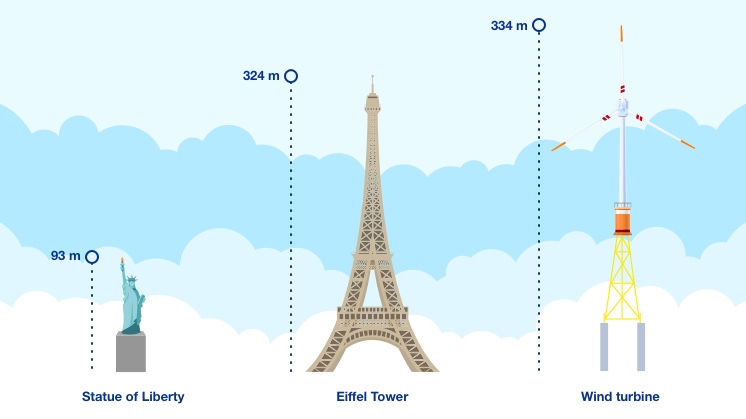

The history of offshore wind has been marked by continuous innovation. The capacity of offshore turbines has increased dramatically over the past few decades. Today's wind turbines are well over 10 MW and even models with up to 22 MW are being launched, according to the Global Wind Energy Council's Global Offshore Wind Report 2022.

This evolution can be clearly seen in the offshore wind projects developed by the Iberdrola group: West of Duddon Sands External link, opens in new window., Wikinger, East Anglia ONE, Saint-Brieuc, Vineyard Wind and Baltic Eagle.

External link, opens in new window., Wikinger, East Anglia ONE, Saint-Brieuc, Vineyard Wind and Baltic Eagle.

Evolution of unitary capacity marinosand rotor of our offshore wind turbines

- 120 m 3.6 MW

- 135 m 5 MW

- 154 m 7 MW

- 167 m 8 MW

- 174 m 9.5 MW

- 220 m 13 MW

How has the power of the turbines been increased?

West of Duddon Sands was the first offshore wind farm Iberdrola commissioned in 2014. Located in the Irish Sea in the United Kingdom, it has 108 wind turbines providing a total of 388.8 MW of power, 3.6 MW each. The circumference described by the blades of each turbine (or rotor) has already reached 120 metres in diameter.

Since then, the power output of the wind turbines has greatly improved. At the Wikinger offshore wind farm in the German Baltic Sea, which has been in operation since 2017, each of the 70 turbines delivers 5 MW and has a turning diameter of 135 metres. This gives a total installed capacity of 350 MW, just 30 MW less than in the UK, but with 38 fewer turbines.

Even more significant are the improvements at East Anglia ONE, a macro offshore wind power project that has been operational since 2020. With 102 turbines with 7 MW unit power and 154 rotor metres, at the time of commissioning East Anglia ONE was the largest offshore wind farm in the world, supplying 714 MW. With six fewer turbines than West of Duddon Sands, East Anglia ONE provides almost twice as much power.

At the Saint-Brieuc wind farm (our first offshore wind farm in Brittany), operational since 2024, 8 MW wind turbines with a 167-metre turning diameter have been installed. This allows us to reach a total installed capacity of 496 MW with only 62 turbines.

However, the largest unit capacity is found at Vineyard Wind 1 and Baltic Eagle. Vineyard Wind 1 (our first offshore wind farm in the US) has an installed capacity of 806 MW supplied by 13 MW wind turbines with 220 rotor metres. Baltic Eagle, located next to Wikinger (in Germany), has 476 MW of capacity generated by 52 turbines with 174 rotor metres and 9.5 MW.

The development of new types of foundations that allow these installations to be located further away from the coast and the continuous evolution in the power and design of wind turbines are just some of the progress we will see in the coming years. These advances undoubtedly augur a long and prosperous future for offshore wind farms.

All the information about

Offshore wind energy

What is offshore wind energy?

Offshore wind energy is obtained by harnessing the power of the wind at sea, where the wind reaches a higher speed and is more constant because there are no barriers. In order to make the most of this resource, mega-structures are installed that are seated on the seabed and equipped with the latest technical innovations.

What are the benefits of offshore wind energy?

Because this is a type of renewable energy, there are numerous benefits because it is inexhaustible (wind is an unlimited resource) and does not pollute. (It is a source of energy that produces low greenhouse gas emissions (GHGs), which are the main culprits responsible for global warming).

The wind blows more at sea than it does on dry land and can produce up to twice the power obtained from onshore facilities. What's more, these plants have a lower visual impact and are less noisy which means that their installed power can be far higher than on land, reaching hundreds of megawatts. Likewise, sea transport is easy, allowing unit powers and sizes far higher than those possible on land.

What is the difference between offshore and onshore wind farms?

The main difference lies in the technological difficulty of building them because the structures and their maintenance are more complex due to the offshore environment, which is governed by strict safety requirements. The construction and operation of offshore wind farms requires the use of highly specialised logistical resources. On the other hand, the capacity to generate electricity is higher offshore, because the wind resource is superior and more regular than it is on dry land, which means a higher yield of power. It is easier to transport the components required to install a wind farm offshore, which is why wind turbines with unit power of over 10 MW - and even 15 MW - are feasible in an offshore setting. It is more difficult to transport them on land, where unit power of around 5 MW is the norm.

Due to access constraints during operation, wind farm elements require higher reliability and components are designed with higher levels of redundancy than onshore wind farms.

What is the environmental impact of an offshore wind farm?

To install an offshore wind farm a positive Environmental Impact Statement (EIS) must be obtained, as well as a favourable study showing the compatibility of the facility with other uses of the maritime space. For this, very rigorous and strict studies must be conducted in the years prior to the start of the project, including an analysis of the compatibility of the wind farm with navigation, marine fauna, avifauna, migration routes, sediment transport dynamics, etc. These studies are complemented by thorough monitoring of these aspects during the construction and operation phases of the farm.

To protect the environment on wind farm sites, the offshore power industry is using cutting edge, extremely innovative solutions. For example, Iberdrola has used advanced noise mitigation systems while building offshore wind farms such as the underwater bubble curtains used for the Wikinger project in the Baltic Sea. This system protects marine mammals from being affected during construction.

Types of offshore wind farms:

There are two types, distinguished by the type of anchorage used to secure the wind turbines:

Marine wind turbines with fixed foundations:

These are installed on a fixed support structure on the seabed. In turn, there are different types of foundations: monopile (the tower is installed on a large steel cylinder embedded in the seabed); gravity-supported (requires a high-mass, large-area concrete or steel platform resting directly on the prepared seabed); or using jackets (reticular steel structures with three or four anchor points on the seabed). Current fixed foundation technology permits structures to be installed up to 60 metres below the surface.

Offshore wind turbines on floating platforms:

This type of technology allows these wind generation farms to be built farther offshore in very deep waters. The floating bases make it possible to harness the enormous potential of the wind in huge offshore areas. With this type of technique, depth restrictions are determined by the laying of underwater electricity evacuation infrastructures, which can be placed hundreds of metres below sea level.

Depending on the system used to fasten the equipment to the sea bed, they are classified as: single floating columns or spars, semi-submersible platforms or tension-leg platforms.