What is 4D printing and how does it work?

4D printing: Is this the Fourth Industrial Revolution?

Clothes that adapt to weather conditions, furniture that assembles itself when taken out of the box, pipes that regulate their width according to the flow, prostheses that adapt to growth and disintegrate once they are no longer needed... These are just some of the present and future applications of 4D printing. Intelligent designs that adapt to the environment and transform over time.

What is 4D printing?

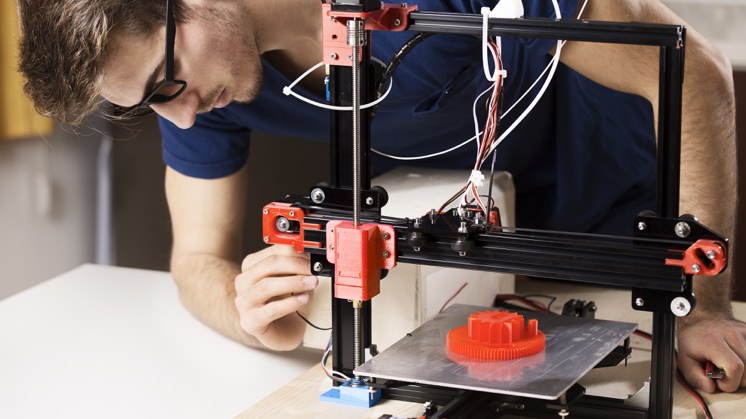

4D printing uses 3D printers to create live three dimensional objects without wires or circuits. It does so by using intelligent materials, which can be programmed to change shape, colour or size when they receive an external stimulus.

Such is the case with hydrogel resins, active polymers or even live tissues. They are printed in 3D with a specific design that evolves over time and when in contact with humidity, light, pressure or temperature, among other factors, to achieve the intended finish.

4D printing makes it possible for an object, for example, to bend, repair, assemble or even disintegrate itself. It acquires a new shape or functionality on its own by reacting with the environment.

4D printing origins

The forefather of this emerging technology is computer scientist Skylar Tibbits, founder and co-director of the Self-Assembly Lab at the Massachusetts Institute of Technology (MIT). It was presented to the world in 2013 and is currently in a research and early adoption stage, it is expected that by 2030 4D printing will move towards wider commercialization, for example in sectors such as healthcare, construction and defense.

The origins of 4D printing is in the introduction of a time factor to 3D printing. It consists of creating three-dimensional objects that adapt to the circumstances of each moment without the intervention of robots or people, only combining materials and geometry with interactions, an energy source and intelligent design, Tibbits explains.

The Self-Assembly Lab is currently experimenting with new 4D printing techniques such as Rapid Liquid Printing, which allows a large sofa to be printed in just a few minutes, and materials such as plastic, rubber or foam.

4D printing applications by sectors

4D printing is destined to revolutionise the industry. These are some of its possible achievements:

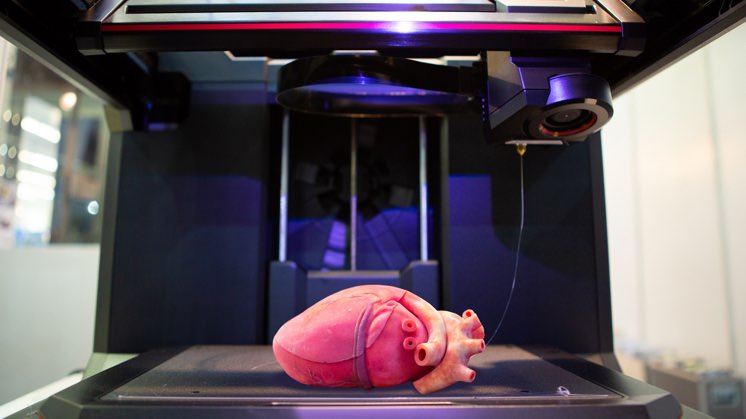

Medicine and surgery

Medicine and surgery

In 2015, a medical team from the University of Michigan saved the lives of three babies with respiratory problems by inserting a 4D printed implant. This polycaprolactone device, designed to fit each patient, was designed to adapt its size to the child's growth and to dissolve itself when no longer necessary.

At present, the use of 4D printing in ultrasound scans allows, for example, to know more precisely the structural and functional development of the nervous system of the foetus.

Stents and other 4D devices that react to body heat and expand to adapt to the patient have also begun to be developed.

Another milestone in medicine is the development of smart medicines that work by releasing drugs in a controlled manner in response to specific changes in the body, improving the efficacy and safety of drug treatments.

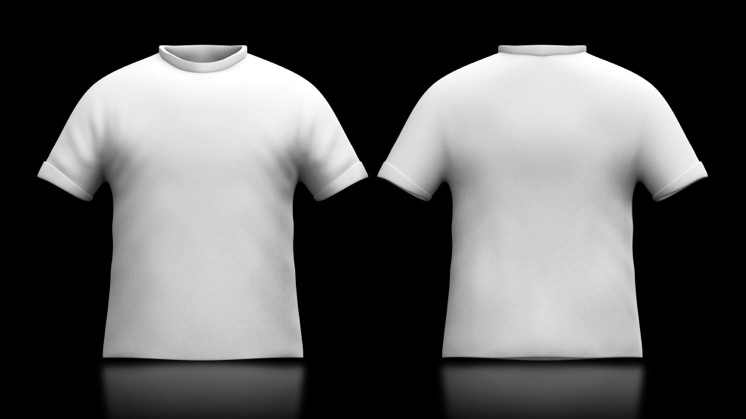

Clothing and footwear

Clothing and footwear

4D printing allows the manufacture of clothing that adapts to the body's shape and movement. The U.S. military is testing, for example, uniforms that change colour depending on the environment, or that regulate perspiration depending on the soldier's pulse or environment temperature.

Another advance is transformable garments that adapt to light, temperature or humidity, adapting the thickness and ventilation of clothing to maintain optimal body temperature.

4D printed shoes will also be able to adapt to movement, impact, temperature and atmospheric pressure.

Aeronautics and automotive

Aeronautics and automotive

The NASA has developed an intelligent metallic fabric with 4D printing. This fabric, which is already used for astronaut suits due to its insulating nature, could also be used to protect spacecraft and antennas against the impact of meteorites. Meanwhile Airbus is testing materials that react to heat to cool its aircraft engines.

Thanks to 4D printing, intelligent airbags can be produced in the future that can anticipate any impact and reduce the risk of injury to the driver and passengers.

In short, we are talking about an untapped technology that will revolutionise the printing and manufacturing of objects over the next few years. The Fourth Industrial Revolution is already underway.

The near future of 4D printing

Sources: Emergen Research, Mordor Intelligence, Industry Talks, Ceplan Observatory, PT Mexico.

SEE INFOGRAPHIC: The immediate future of 4D printing [PDF] External link, opens in new window.

SEE INFOGRAPHIC: The immediate future of 4D printing [PDF] External link, opens in new window.

What is Augmented Reality?

Increasingly more in demand, this technology’s development in recent years has been exceptional.

Advantages and uses of biometrics

But the truth is that we are seeing it more and more in our daily lives and they say it will soon end up replacing our passwords or door keys.