What are submarine cables?

Why are submarine cables essential for the global interconnection of electricity grids?

Submarine power transmission cables are a key tool in the energy transition, as they enable the transport of large volumes of electricity efficiently and securely across seas and oceans. Thanks to their advanced technology and their role in integrating renewable energy sources, these types of cables are driving the development of a more sustainable and interconnected energy system. Discover how they work, how they are installed, their contribution to the energy transition and their potential applications in the future.

Submarine cables are not visible, but they are more present in our world and daily lives than we might imagine. Currently, millions of kilometres of these cables cross the planet beneath vast bodies of water to enable instant connections between continents, companies and people.

While this kind of infrastructure is mainly associated with sectors such as telecommunications (internet, telephony and data transmission), its role in securing the global electricity supply is particularly relevant, especially for major consumers such as industry and the electrification of transport. The definition itself highlights the crucial role in the energy transition:

Submarine power cable systems are an infrastructure designed to transmit high-voltage electricity beneath seas and oceans, connecting offshore wind farms with onshore grids, linking electrical systems in different countries or even supplying electricity to remote areas. Made from highly resistant materials and protected by metal armouring, these cables enable efficient and safe electricity transmission, minimising losses and strengthening supply stability over long distances.

The history of submarine cables is largely linked to the development of telecommunications, with pioneering efforts dating back to the mid-19th century to support the telegraph. However, according to the European Subsea Cables Association (ESCA), the first submarine cable to transmit electricity was laid across the River Isar in Bavaria in 1811. Since then, underwater connections have evolved thanks to technological advances, constantly increasing their capacity and length.

How submarine cables work in electricity transmission

By definition, submarine power cables carry high-voltage electricity beneath seas and oceans, enabling the connection of different electrical grids and infrastructure across the sector.

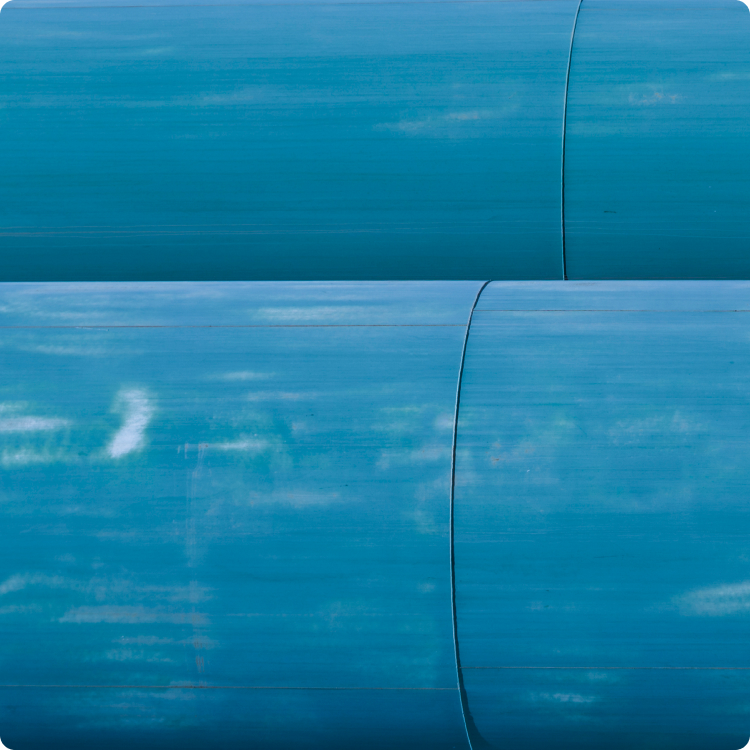

Typically, these cables range from 70mm to over 210mm in diameter and are available in two types: alternating current (HVAC) and direct current (HVDC). The choice depends mainly on the route length, voltage, transmission capacity and synchronisation with the grid. Generally, alternating current is more cost-effective for distances under 80km, while direct current technology offers better performance for longer distances. Increasingly higher voltages are being introduced to extend their reach.

Anatomy of a submarine power cable

The laying conditions and infrastructure determine the type of submarine cable used. Below are the key components of two of the most commonly used examples in AC and DC installations.

Source: European Subsea Cables Association.

The operation of submarine cables is integrated into the process of electricity generation and transmission. The following are some key steps:

Differences with submarine energy cables

While submarine telecommunications cables are designed to transmit data signals via optical fibres, power cables transmit very high-voltage electricity. The former are thinner and lighter. Power cables, on the other hand, are much more robust and heavy, with layers of insulation and shielding to withstand the harsh conditions of the ocean.

Another key difference is the use of repeaters. These are a core component of telecommunications cables used to amplify optical signals, whereas submarine power cables do not use them in the traditional sense. Instead, they rely on converter stations located at each end of the route to convert the current and optimise transmission. These stations are based on the latest power electronics technology.

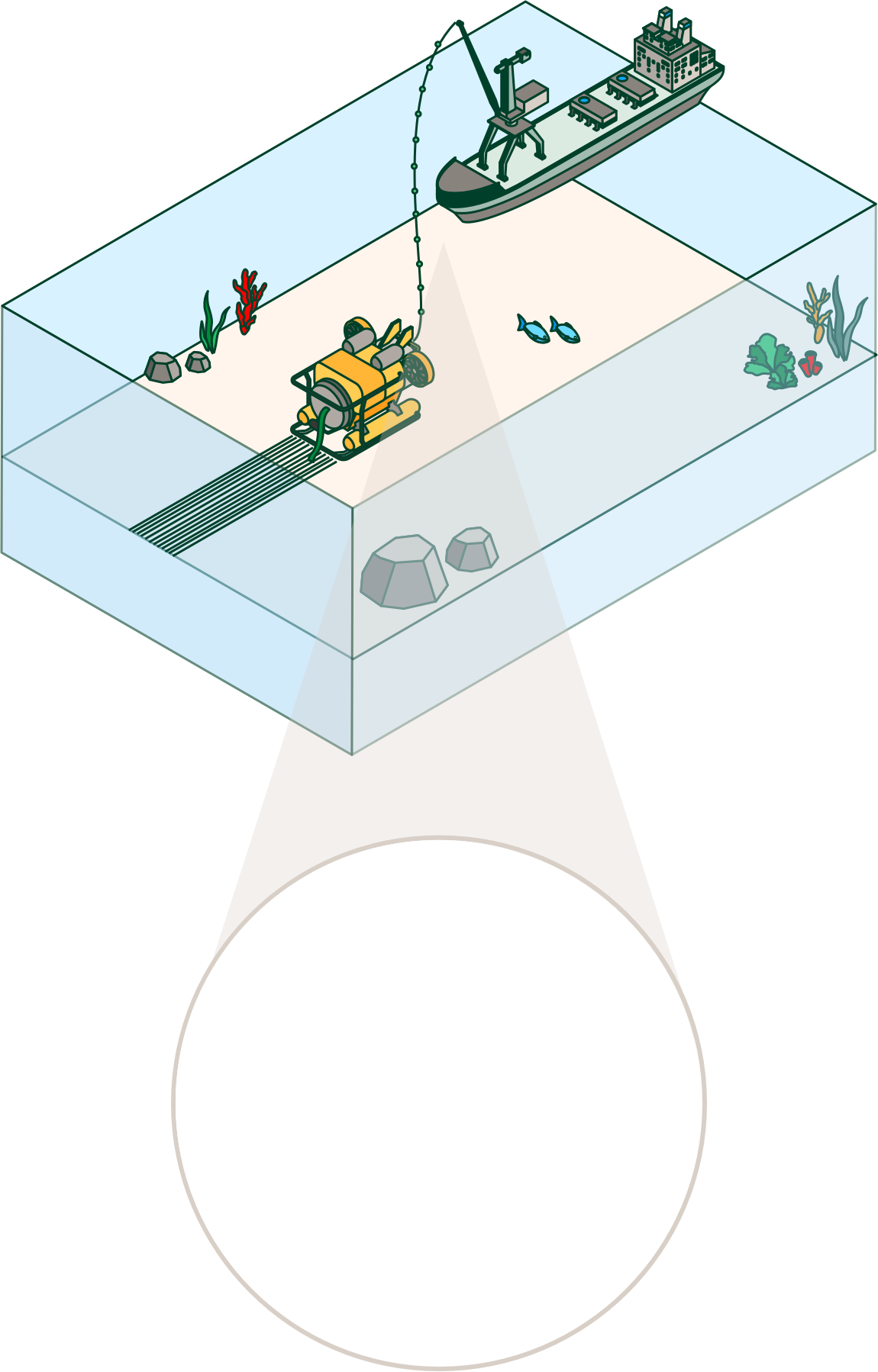

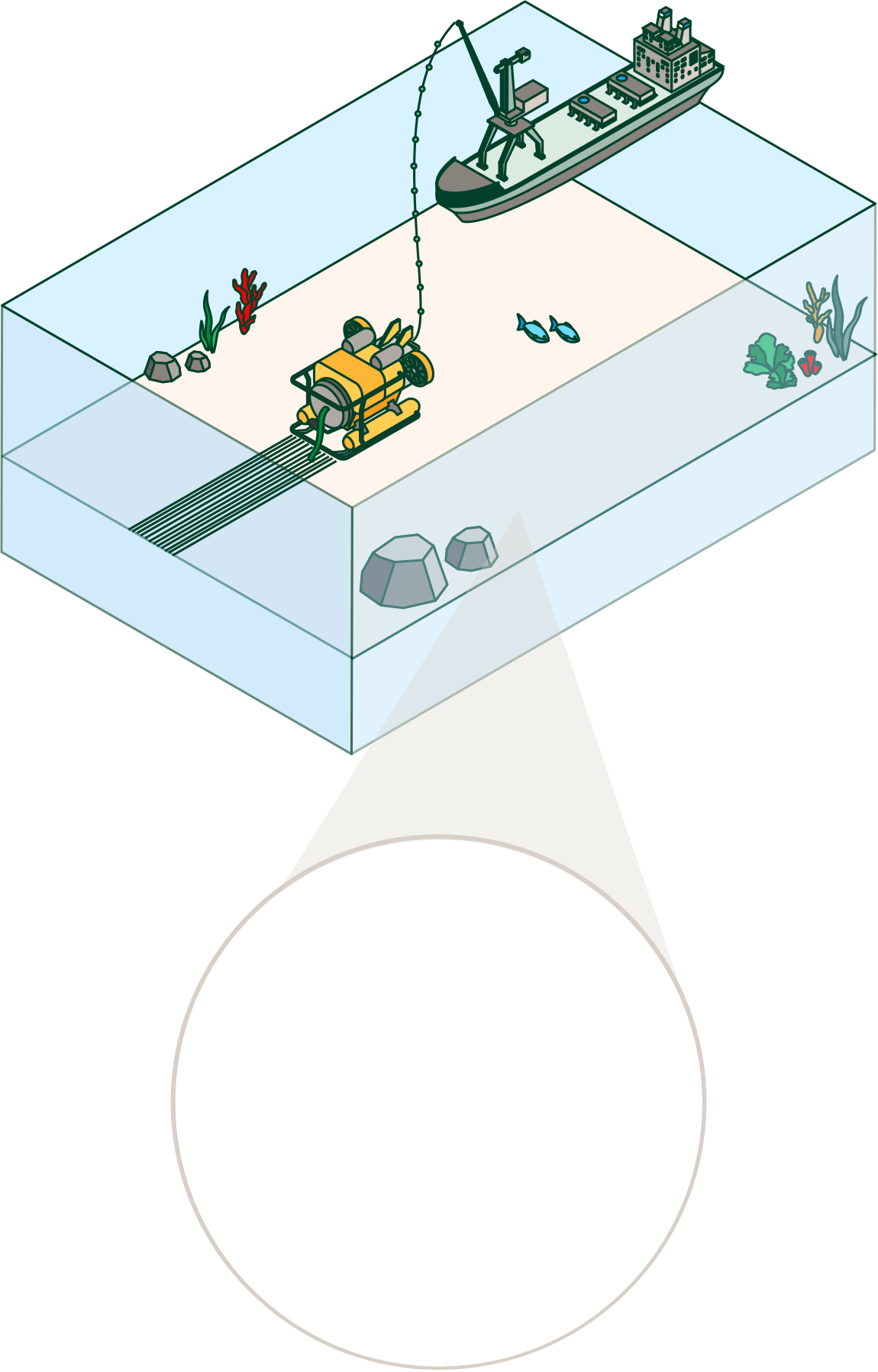

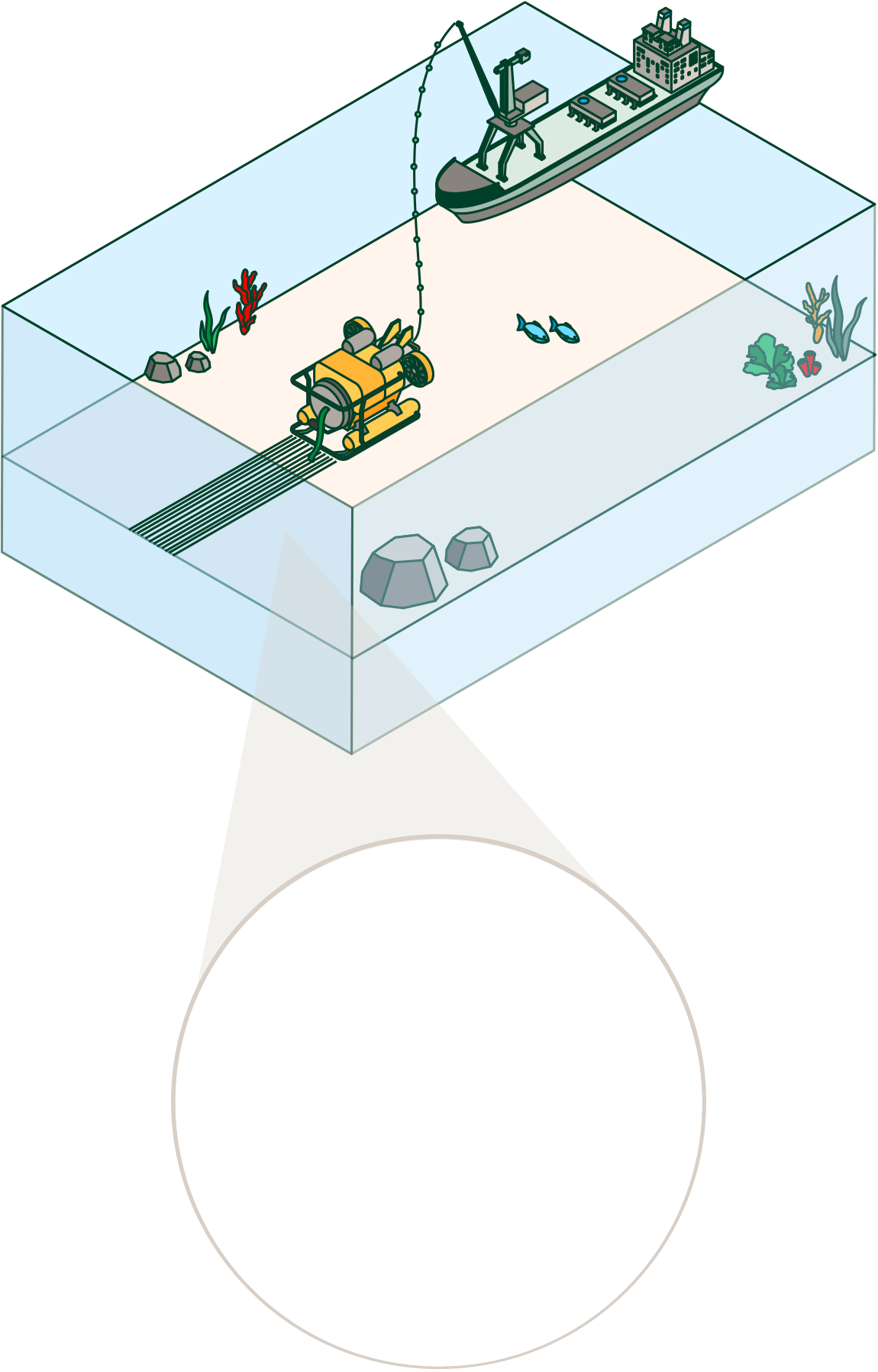

How is a submarine cable installed on the seabed?

The installation of a submarine cable is a complex process that can take several years from planning to operation. Its assembly and maintenance require high levels of technological and logistical expertise. These are some of the key phases in the installation process:

1 Route study and selection

A detailed survey of the seabed is first carried out using geotechnical surveys and subsea mapping. Factors such as depth, seismic activity, the presence of sensitive ecosystems and maritime traffic are analysed to choose the optimal route that ensures safety and efficiency.

2 Cable manufacturing and testing

Once the route has been defined, the cable segments are manufactured. Each section undergoes resistance, insulation and durability tests before being transported to the installation site.

3 Cable transport and laying

The cable is loaded directly from the factory onto specialised vessels (cable-laying vessels), equipped with large reels, advanced positioning systems and remotely operated robotic underwater tools. During deployment, the vessel follows the planned route and slowly lays the cable on the seabed.

Whenever possible, the preferred option is to bury the cables beneath the seabed to protect them from potential damage. The most common method is cable ploughing:

4 Final connection and testing

Once the cable is installed, connections are made at the converter stations at both ends, and transmission tests are conducted to verify correct operation before going live.

Source: European Subsea Cables Association, ZMS Cable.

Daños y reparación de los cables submarinos de energía

The manufacturing and installation of submarine cables must be carried out with precision and care to ensure the systems function properly and are not affected by external factors. A major fault in a submarine power cable can have serious consequences for the stability of an electricity grid. In the case of international interconnections, it could cause blackouts or overloads in other lines. In regions that depend exclusively on these cables, such as islands or remote areas, disruption could lead to an energy crisis until repairs are completed.

The greatest risk occurs during installation. The mechanical stresses placed on the cable may show immediate effects or surface years later, according to the ESCA. However, once installed, cables also face several external hazards. For example, marine forces can damage the cable’s sheath and insulation, allowing moisture or water to penetrate. As a result, electrical resistance can be significantly reduced. For this reason, most submarine cables are equipped with waterproofing measures.

Cables may also be damaged by fishing trawlers and ship anchors. Cable owners often address this risk through awareness campaigns providing information about cable locations.

To repair a damaged cable, technicians must bring it to the surface and separate it into two sections. A new piece of cable is usually spliced in to reconnect the original ends. Each time a cable is repaired, it becomes slightly longer than it was when first installed.

Advantages and disadvantages of submarine power cables

The use of submarine cables has multiplied over recent decades, especially due to the development of offshore wind farms and the improvement of electricity supply security between countries or regions. However, like any technological infrastructure, they come with both benefits and challenges.

Market

CloseAdvantages

Faster legalisation process

Submarine cables are easier to legalise than land lines, as they do not cross private property or require approvals from as many authorities. This makes it possible to move forward with large-scale projects, such as cables hundreds of kilometres long, in relatively short timeframes. One example is the planned interconnection between Morocco and the UK to transport energy generated from solar.

Disadvantages

High demand and dependence on manufacturers

The submarine cable market is overwhelmed by growing demand, and the main manufacturers cannot meet all production needs. This gives them significant power, making it necessary for utilities to secure agreements years in advance to guarantee supply.

Manufacturing

CloseAdvantages

Greater technical reach

Unlike HVAC cables, which suffer significant reactive losses and are limited in range (around 120km at 220kV), HVDC submarine cables have no technical limitations on length. This enables the development of interconnection projects stretching thousands of kilometres, such as the ongoing cable system being built between Australia and Singapore.

Disadvantages

Costly infrastructure and long-term planning

The manufacturing and laying of submarine cables requires coastal factories and specialised ships, which involve large investments. Manufacturers therefore prioritise large-scale projects that justify these costs. In addition, project execution requires long-term planning, with schedules often locked in up to five years before installation.

Transportation and technology

CloseAdvantages

Long-distance energy transmission

Long submarine cables allow energy generated in wind farms located more than 120km offshore to be transmitted. Although this has not yet been developed in Spain due to the depth of its continental shelf, it is key to harnessing offshore potential in other countries.

Disadvantages

Constantly evolving technology

HVDC cables are undergoing rapid technological development, unlike AC cables, which are already a mature technology. In just a few years, their voltage capacity has increased from 400kV to 525kV, and new cable technologies such as P-LASER and PPL have emerged, while traditional technologies such as impregnated paper still coexist.

Renewable energies

CloseAdvantages

Stability for renewable-based grids

When connected to HVDC-HVAC converter stations, HVDC cables provide synthetic inertia and help regulate frequency, voltage and reactive power in the grid. This makes them particularly valuable in systems with high renewable penetration and low synchronous generation, as is the case in the UK.

Submarine cables in the electrification of the economy (use cases in electricity infrastructure)

Submarine power cables are key infrastructures for electrification because they enable the integration of renewable energy sources and strengthen interconnections between electricity grids in different countries and regions. The main scenarios in which these infrastructures are used in the energy sector include:

Connecting offshore wind farms to the onshore grid

Renewable energy interconnections between regions

Electricity supply to islands and remote areas

Connecting offshore wind farms to the onshore grid

Renewable energy interconnections between regions

Electricity supply to islands and remote areas

The advantages provided by submarine cables in the shift towards a more sustainable and renewable world are based on two core ideas: they are more efficient and more cost-effective than other transmission infrastructures. Some of their main contributions to electrification include:

Energy loss reduction

The use of HVDC cables significantly reduces electricity losses over long distances, making them more efficient than overhead or underground lines.

Greater safety and resistance to extreme weather

These infrastructures are not exposed to storms, high winds or wildfires, which affect land-based infrastructure.

Long-term savings

Despite the installation cost, their energy efficiency and reduced reliance on fossil fuels make them a profitable long-term investment.

Iberdrola’s submarine cable projects

At Iberdrola we are promoting electricity grids as a key driver for integrating clean energy in the countries where we operate, through major submarine cabling projects.

One such project is Western Link, the world’s highest-capacity submarine connection, launched in 2018 through our subsidiary ScottishPower and National Grid, the UK electricity system operator. The installation involved an investment of €1.2 billion. This infrastructure includes a high-voltage cable, Western Link, External link, opens in new window. which is 850 kilometres long – 770 of which are submarine – and connects the west coast of Scotland to Quay Bay, on the north coast of Wales. The connection is bidirectional, meaning the electricity flow moves north or south depending on supply and demand. It has increased interconnection capacity by more than 2,200 megawatts (MW).

External link, opens in new window. which is 850 kilometres long – 770 of which are submarine – and connects the west coast of Scotland to Quay Bay, on the north coast of Wales. The connection is bidirectional, meaning the electricity flow moves north or south depending on supply and demand. It has increased interconnection capacity by more than 2,200 megawatts (MW).

We are also looking ahead to the future with two new projects underway. One is Eastern Green Link 1 (EGL1), a 2GW high-voltage direct current connection between Torness, in East Lothian (Scotland), and Hawthorn Pit, in County Durham (England). The multi-billion pound project External link, opens in new window. is being developed through a joint venture between SP Energy Networks and National Grid Electricity Transmission (NGET). Its bidirectional design will enable the use of Scotland’s renewable energy reserves to boost the UK’s grid capacity. After starting connection works in 2024, EGL1 is expected to be fully operational by 2029, with the capacity to supply electricity to two million homes.

External link, opens in new window. is being developed through a joint venture between SP Energy Networks and National Grid Electricity Transmission (NGET). Its bidirectional design will enable the use of Scotland’s renewable energy reserves to boost the UK’s grid capacity. After starting connection works in 2024, EGL1 is expected to be fully operational by 2029, with the capacity to supply electricity to two million homes.

We are also working on the Eastern Green Link 4 (EGL4) External link, opens in new window. project, a new high-voltage direct current (HVDC) electricity connection that will link Fife, in Scotland, with Norfolk, in England. These facilities and projects will play a key role in the UK’s energy transition towards net-zero emissions.

External link, opens in new window. project, a new high-voltage direct current (HVDC) electricity connection that will link Fife, in Scotland, with Norfolk, in England. These facilities and projects will play a key role in the UK’s energy transition towards net-zero emissions.

Trends and the future of submarine cables in the energy sector

Submarine cables are evolving rapidly to address the challenges of the energy transition, the rise of digitalisation and the growing demand for global interconnections. As a result, the trend points to growth in these networks. Market research firm Mordor Intelligence estimates that the submarine electricity transmission systems market will grow at a compound annual rate of over 14% between 2024 and 2029.

One of the main drivers of this growth is the expansion of wind power generation, particularly offshore wind, and the declining cost of electricity production using this technology. What’s more, Mordor Intelligence identifies the push to protect biodiversity and marine ecosystems, along with efforts to minimise the footprint of large submarine electricity systems, as a significant opportunity for the sector. By region, the Asia-Pacific area is expected to lead this development due to a steady increase in electricity consumption across those territories.

These trends are also expected to foster innovation in materials and design, automation and digitalisation, and the development of supercables to support global interconnections.