Uses, features and applications of drones

Drones: how unmanned aerial vehicles are transforming industry

Drones are no longer futuristic devices. In just a few years, these unmanned aerial vehicles (UAVs) have become essential tools in fields as diverse as renewable energy, environmental monitoring or emergency response. Thanks to the combination of artificial intelligence, advanced sensors and real-time data analytics, drones are helping companies become safer, more efficient and more sustainable. This is especially relevant in the electricity sector, where drones have evolved from a complementary technology to playing a key role in a wide range of tasks.

Drones are small aerial devices operated remotely. Depending on their model and function, they may resemble a miniature helicopter with four or more rotors or a small fixed-wing aircraft with wings and propellers. Their compact size, low weight and, above all, the fact that they do not require an onboard pilot make them extremely versatile tools that can adapt to a wide range of environments and needs.

The small size of their components means some drones fit inside a backpack or even in the palm of a hand, which makes them indispensable allies in a broad variety of scenarios. They can monitor endangered species, detect water or gas leaks, locate people in emergencies, support weather forecasting, streamline inspection and maintenance tasks on electricity networks or even perform deliveries.

The global drone market is expected to reach €90 billion by 2030, with a compound annual growth rate close to 14%, according to consultancy Mordor Intelligence, which forecasts significant expansion across the sector.

The drone market can be divided into four major segments: the recreational segment aimed at hobby users; the military segment that includes surveillance and even combat operations; the commercial segment, such as filming for audiovisual media; and the industrial segment.

Today, drones have become essential tools across many sectors because they help reduce costs, improve safety conditions and accelerate processes. Below, we look at how they are used in different industries, particularly in the energy sector, and how the Iberdrola group is harnessing their full potential.

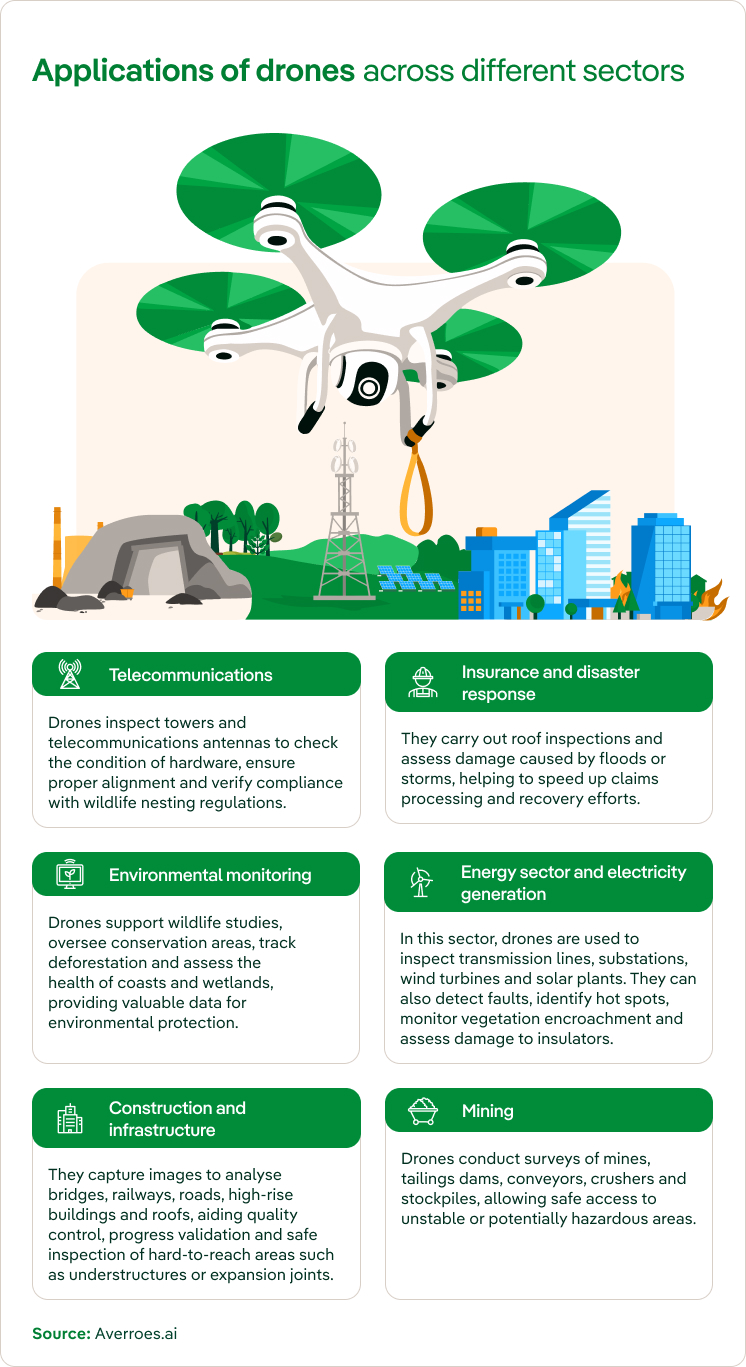

SEE INFOGRAPHIC: Applications of drones across different sectors [PDF]

SEE INFOGRAPHIC: Applications of drones across different sectors [PDF]

Advantages of drones

Using drones for industrial inspections offers a smarter, safer and more sustainable alternative to traditional methods, such as helicopters or manual checks. By eliminating the need for workers to climb structures, enter confined spaces or face high temperatures or chemicals, drones drastically reduce occupational risks and simplify regulatory compliance. They also provide a clear environmental advantage: replacing helicopters with drones significantly cuts CO₂ emissions, contributing to companies’ sustainability goals.

Drone inspections are not only safer but also faster and more efficient. Routine flights can cover large areas in just a few hours, allowing potential issues to be identified early and monitored in real time. They are also far more cost-effective, removing the need for scaffolding, cranes, rope access teams or manned aircraft, while minimising downtime and reducing site visits. Additionally, drones capture high-resolution images, thermal data and LiDAR scans – a remote sensing method that creates 3D models of the environment – providing precise and repeatable measurements.

When combined with AI-driven analytics, this data improves accuracy, speeds up inspections and enables more informed maintenance decisions. Each flight generates a detailed, georeferenced and timestamped record, reinforcing traceability and allowing consistent year-on-year comparisons, making drone technology a cornerstone of modern, efficient asset management.

Drones in the electricity sector

Traditionally, inspections of power lines were carried out manually, a time-consuming process that relied on workers collecting visual data. The work could be hazardous, with exposure to harsh weather conditions. Manned helicopters were also sometimes used, but they carried risks for operators and were extremely costly.

Industry estimates suggest that inspecting 500 kilometres of power lines annually could cost €105,000 using a helicopter and a full crew, compared with €55,800 in the first year using drones, and just €12,500 per year thereafter once the initial investment has been made.

Modern drones offer an attractive alternative for power line inspections and have been increasingly deployed worldwide in recent years. UAVs are now considered a key tool for inspection, mapping and predictive maintenance of this critical infrastructure.

The advantages of drones in the electricity industry

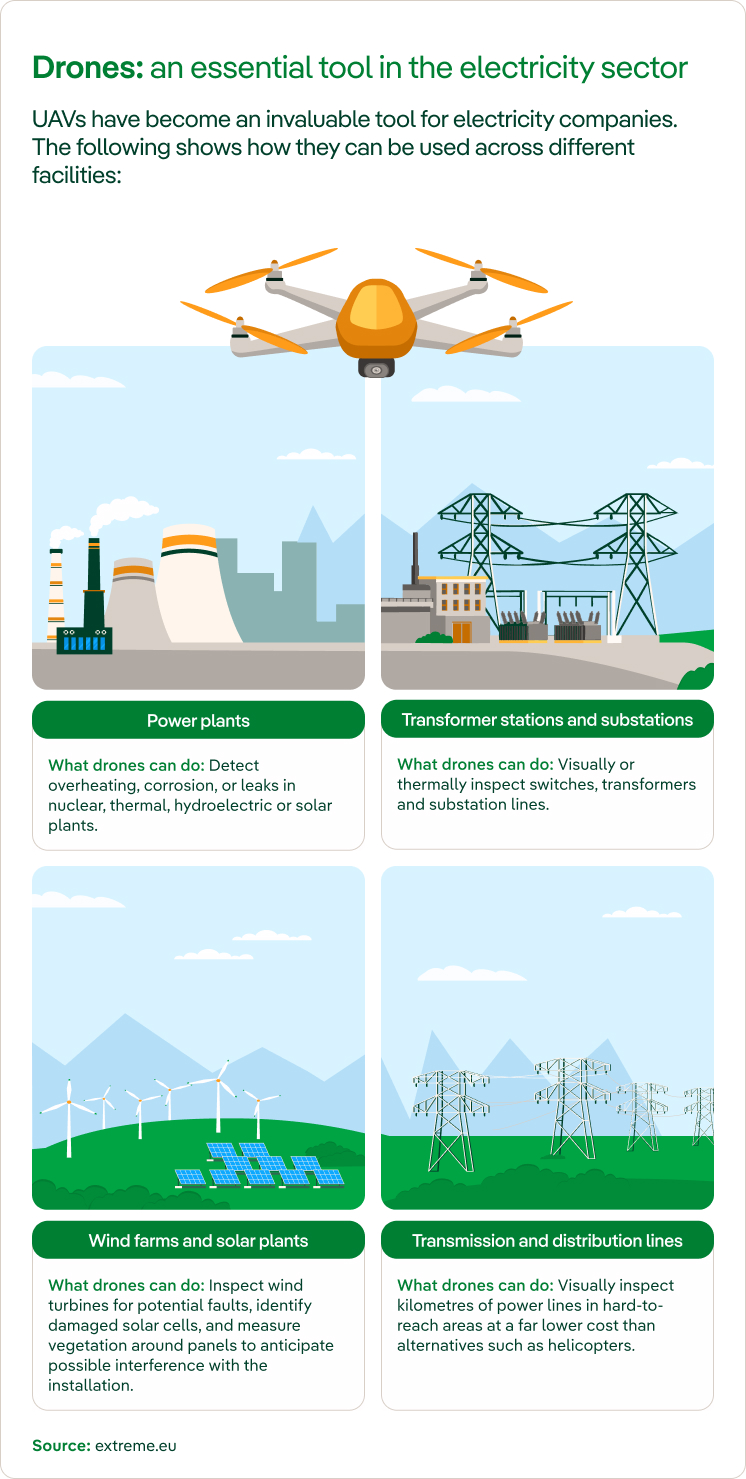

SEE INFOGRAPHIC: Drones: an essential tool in the electricity sector [PDF]

SEE INFOGRAPHIC: Drones: an essential tool in the electricity sector [PDF]

How Iberdrola uses drones

At Iberdrola, we were among the first energy companies to recognise the enormous potential of drones and their ability to transform how large-scale energy infrastructure is monitored and maintained. Since 2013, through our international PERSEO programme, we have invested in initiatives such as the Spanish start-up Arbórea Intellbird, developing specialised solutions for the inspection and maintenance of onshore wind turbines.

Today, drones are a key element of Iberdrola’s broader digital transformation strategy, alongside data analytics, automation, and robotics, helping to enhance worker safety, reduce environmental impact, and improve operational efficiency.

Autonomous drones are already being used in confined spaces at the Cofrentes nuclear power plant, while Avangrid, Iberdrola’s US subsidiary, has inspected more than 38,000 kilometres of power lines using drones, specialised vehicles, and artificial intelligence. The company also developed the Aracnocóptero, a drone capable of autonomously flying around wind turbines to capture high-resolution images for remote inspections.

In Australia, drones have been incorporated into the operation and maintenance of solar installations, helping to optimise assets and generate imagery for the development of new projects.

Iberdrola is also leading several R&D initiatives to advance drone technology applied to energy. Through projects such as AZTERTUZ, funded by the Basque Government and the European Union, we are researching inspection technologies based on deep learning to automate asset diagnosis and maintenance.

At the same time, we are exploring new uses for drones and robotics in solar plants. While the upper surface of solar panels can be easily inspected with aerial drones, checking the underside – where most wiring and connections are located – still requires manual work. Iberdrola is now testing advanced technologies to automate these inspections ↗ using small drones or ground robots capable of operating beneath the panels.

Through PERSEO, we have launched an open innovation challenge for start-ups offering imaging and data analysis solutions, aiming to first apply these technologies in Spain and then scale them across our international solar operations.

The future of drones in industry

The next generation of drones will go beyond merely collecting data. Thanks to advances in artificial intelligence and automation, autonomous fleets will operate collaboratively to inspect, repair, and monitor infrastructure in real time. In the energy sector, they will play a key role in achieving digitalisation, decarbonisation, and safety objectives.

Moreover, authorities such as the Federal Aviation Administration (FAA) in the United States are relaxing restrictions on drones, which will allow greater access to airspace in the future. Whether by reducing risks to humans, generating smarter data, or speeding up inspections, drones are transforming the industry for the better and are expected to continue doing so for decades.