Predictive maintenance

Predictive maintenance: the key data-driven technique for anticipating errors

If a machine develops a fault, the negative repercussions for a company in terms of both service and finances can be enormous. This is why more and more companies are opting for predictive maintenance, a series of actions and techniques that are applied with the aim of anticipating errors. Below, we explain in detail what it consists of and what its main advantages are.

In the 19th century, steam locomotives required constant maintenance. Manual lubrication - operators had to walk around the moving parts every few kilometres and check which ones needed oil - it was essential to prevent them from overheating. The machinery used in transport today is more sophisticated, but maintenance is still necessary to avoid breakdowns and, as with the old locomotives, it is more cost-effective to detect faults early. Predictive maintenance helps do this.

What is predictive maintenance

Predictive maintenance is a technique that uses data analysis tools and techniques to detect operational anomalies and potential defects in equipment and processes so that they can be addressed before failure occurs. Just as predictive analytics can anticipate, for example, market movements or fluctuations in energy demand, predictive maintenance uses data analytics to anticipate system failures and is a fundamental part of the Industrial Internet of Things (IIoT).

How predictive maintenance works

To monitor the condition of equipment and alert technicians to upcoming failures, preventive maintenance has three main components:

- Sensors and connected devices installed on machines send data on machine status and performance in real time thanks to the Internet of Things (IoT), technologies, which enable communication between machines and analytics systems.

- Software solutions and cloud computing allow data mining to be applied to collect and analyse huge amounts of information using big data applications.

- Predictive models are fed with the processed data and use machine learning technologies to establish patterns and comparisons, make predictions of failures and schedule maintenance before they occur.

Predictive, preventive and corrective maintenance: differences

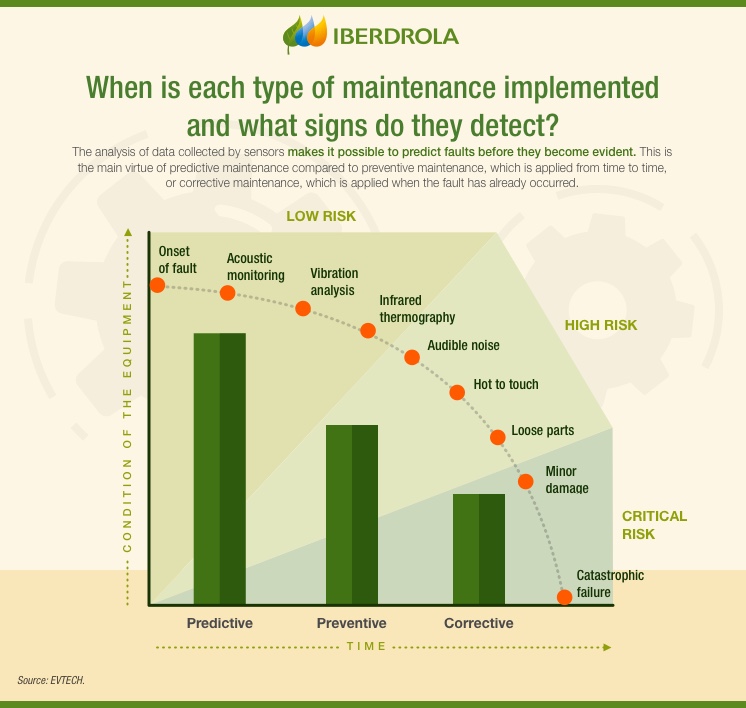

Predictive maintenance is different from preventive and corrective maintenance. However, they can all be used in industry simultaneously. We review their differences below:

- Preventive: consists of inspecting machinery from time to time, whether or not it needs to be inspected, or doing so when some symptom is detected (e.g. a strange noise).

- Corrective: also called reactive or breakdown, it is executed when a fail has already occurred and the damaged equipment needs to be repaired.

- Predictive: a data-driven, proactive maintenance method designed to analyse the condition of equipment on an ongoing basis and foresee potential failures.

Characteristics of predictive maintenance

Predictive maintenance allows the frequency of maintenance to be as low as possible. When maintenance is simply scheduled from time to time (preventive), two things can happen: either it is carried out when it is not necessary - ahead of time or late - incurring avoidable costs, or it is not frequent enough, with the risk of an equipment fault. Therefore, the aim of predictive maintenance is to optimise the use of maintenance resources.

Advantages and disadvantages of predictive maintenance

Predictive maintenance ensures that equipment is only shut down before an imminent fault. This reduces operating costs, minimises downtime and improves overall machine performance. However, the investment in monitoring equipment required for this type of maintenance is often high, as is the level of knowledge and expertise required to interpret the data.

PREDICTIVE MAINTENANCE TECHNIQUES

There are a number of techniques linked to predictive maintenance and we review some of them below:

Infrared thermography

Worn parts and components, including electronic circuits, often emit more heat than normal. By using infrared (IR) cameras, maintenance personnel are able to detect high temperatures (hot spots) on equipment.

Acoustic monitoring

Acoustic sensors enable maintenance personnel to detect gas, liquid or vacuum leaks in equipment. Friction and stresses in machines from worn or poorly lubricated bearings can also be detected.

Vibration analysis

It allows technicians to analyse the vibrations of a machine by means of sensors integrated into the equipment. A machine operating under optimal conditions has a specific vibration pattern, but when components wear out the vibration frequencies change.

Examples of predictive maintenance

Many industries use predictive maintenance to save costs and improve the quality of their services. These are just some examples:

Electricity grids and wind turbines

Outages in electricity distribution systems are very costly. Hence, the progress in the installation of smart grids that make it possible to know the necessary maintenance of assets and therefore anticipate breakdowns. Predictive is also applied to wind turbines to the detriment of corrective in order to avoid downtime and the consequent potential loss of production.

Railway lines

Rail networks and the trains that run on them require constant maintenance. Using IoT, railway companies can identify problem areas on the network, optimise operating times and reduce the impact of breakdowns.

Maritime transport

Monitoring the condition of a ship's machinery allows remote diagnostics to be carried out from shore offices to optimise maintenance operations and achieve maximum vessel performance.